Armor CM Lodestar D8+ Chain Hoist Road Case

This road case is designed to safely transport and store a CM Lodestar D8+ electric chain hoist, a widely used lifting solution in the entertainment and rigging industries. Built for professional touring, staging, and production environments, the case provides structured support to protect the hoist during transport and storage.

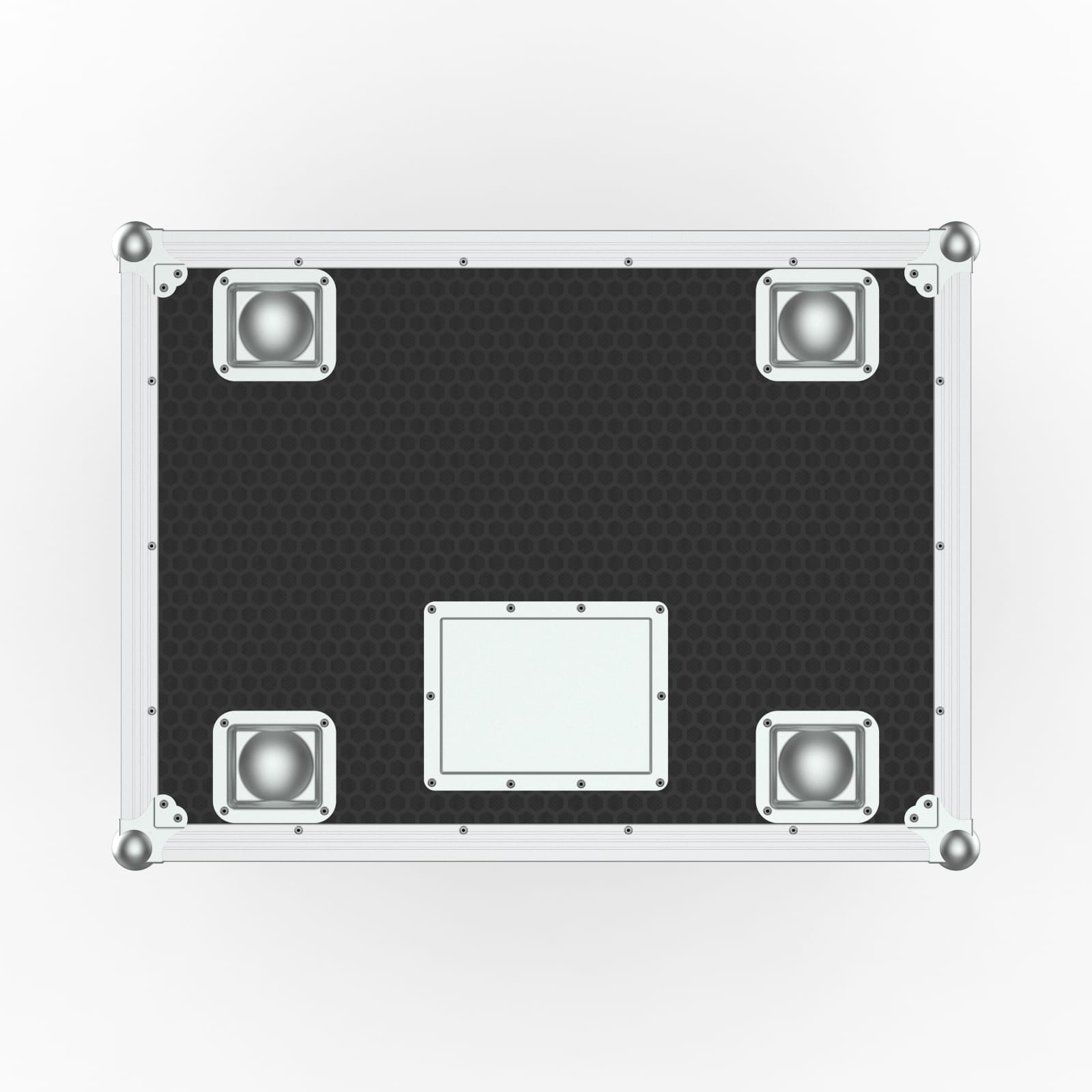

The internal plywood structure helps secure the chain hoist while foam padding minimizes vibration and movement. The hinged lid design allows easy access during setup and pack down, while recessed handles and large latches improve handling and security. Castor dishes allow safe stacking, helping maximize storage efficiency in trucks and warehouses. Designed with truck friendly dimensions and professional hardware, this road case offers a dependable transport solution for production teams working with stage rigging equipment.

SKU:

RIG-CM-1TD8P

Categories: Motor & Controller Cases, Utility & Touring Logistics

Description

Product Specifications

Package Weight and Package Dimensions are for shipping purposes only. Actual product weight and dimensions can be found in the 2D drawing PDF.

| Weight | 48.1 kg |

|---|---|

| Dimensions | 79 × 59 × 66.2 cm |

| Panel |

9MM BIRCH VENEER PLYWOOD WITH HPL EXTERIOR FACE |

Technical Doc.

| 2D Drawing | Download |

Designed for CM Lodestar D8+ Chain Hoist Transport

This road case is purpose built for transporting a CM Lodestar D8+ electric chain hoist, an industry recognised lifting solution commonly used in entertainment, staging, and rigging environments. The CM Lodestar D8+ hoist is known for its high safety standards, durable cast aluminum construction, and double brake system, making it a preferred choice for stage and production lifting applications. Due to the precision mechanical components and internal brake systems within the hoist, controlled storage and protection during transport is essential.

The internal layout of this road case is designed to hold a single CM Lodestar D8+ chain hoist securely. A reinforced plywood support structure helps stabilize the equipment while preventing unwanted movement. This controlled storage approach helps protect both the mechanical and electrical components of the hoist during transportation between venues, storage facilities, and production sites.

Durable Materials and Consistent Manufacturing Standards

The case is constructed using 9 mm birch veneer plywood with a high pressure laminate exterior face and PVC interior face. This combination provides strong resistance to impact, moisture, and wear while maintaining a professional appearance suitable for touring environments.

All structural panels are precision cut using CNC machinery to ensure accurate fit and consistent build quality. Assembly is completed by trained technicians using Penn Elcom hardware, with attention given to lid alignment, latch positioning, and overall structural durability. A standard quality control process is followed throughout production to ensure each case meets Armor’s build and performance standards.

Functional Features Designed for Touring and Rigging Applications

The case features a hinged lid design that allows easy access to the chain hoist during setup and pack down. A corner handle mounted on the lid assists with safe opening and closing, improving usability during fast-paced stage environments.

A reinforced plywood internal structure is designed to hold the hoist securely, helping prevent movement during transport. Foam padding is positioned to absorb vibration and protect sensitive lifting components.

Two large latches provide secure closure, while four recessed handles improve handling and transportation. Castor dishes integrated into the lid allow safe stacking with other cases, helping maximise storage efficiency in trucks and production warehouses. A label dish is also included to allow easy identification of equipment during touring logistics.

Your Case is Our Case

This workstation case features:

We put a lot of efforts in our case designs as well as built quality and workmanship. We design our cases to be long lasting, easy to use and appreciated by our customers.

- Low base, edge customer board, smaller castor wheels for best stability

0%

Why Choose Our Cases

Durability

Our custom built flight and road cases are backed with 5 years warranty. Our transport cases are built by experienced case builders using premium hardware and panels.

Customization

Our case designers are experienced with case designs. 3D scanning technologies and CAD software enable them to accurately design and visualize the cases before production.

Precision Manufacturing

We invest in the best technologies in case making industry including CNC routers, foam cutters, laser cutters, pneumatic aluminum cutting machines, hole punching machines, etc. These tools help to ensure manufacturing accuracy and consistency.

Value to Customer

Production automation using new technology and reduce labor cost by embracing an "Local workshop plus Overseas Factory" model allows us to provide better value for our customer. Covering both urgent and non-urgent orders while not compromising on quality.

Small Wheels, Closer to Edges

This ramp road case is purpose‑built for the Adams Professional Gen 2 29inch, a large and heavy wheeled musical instrument that deserves a little extra pampering on the road. Designed for easy front loading, the case features a hinged lid with an integrated ramp that lets you roll the instrument straight in without the usual wrestling match. Its truck‑friendly dimensions and solid wheels make moving it around surprisingly manageable, even when the gear inside weighs more than your drummer’s entire kit. Built with durability in mind and fitted with premium hardware, this case gives your instrument the protection it needs while keeping transport simple and stress‑free.

SEND US A MESSAGE

Additional information

| Weight | 48.1 kg |

|---|---|

| Dimensions | 79 × 59 × 66.2 cm |

| Panel |

9MM BIRCH VENEER PLYWOOD WITH HPL EXTERIOR FACE |

Reviews (0)

Rated 0 out of 5

0 reviews

Rated 5 out of 5

0

Rated 4 out of 5

0

Rated 3 out of 5

0

Rated 2 out of 5

0

Rated 1 out of 5

0

Be the first to review “Armor CM Lodestar D8+ Chain Hoist Road Case” Cancel reply

Reviews

Clear filtersThere are no reviews yet.