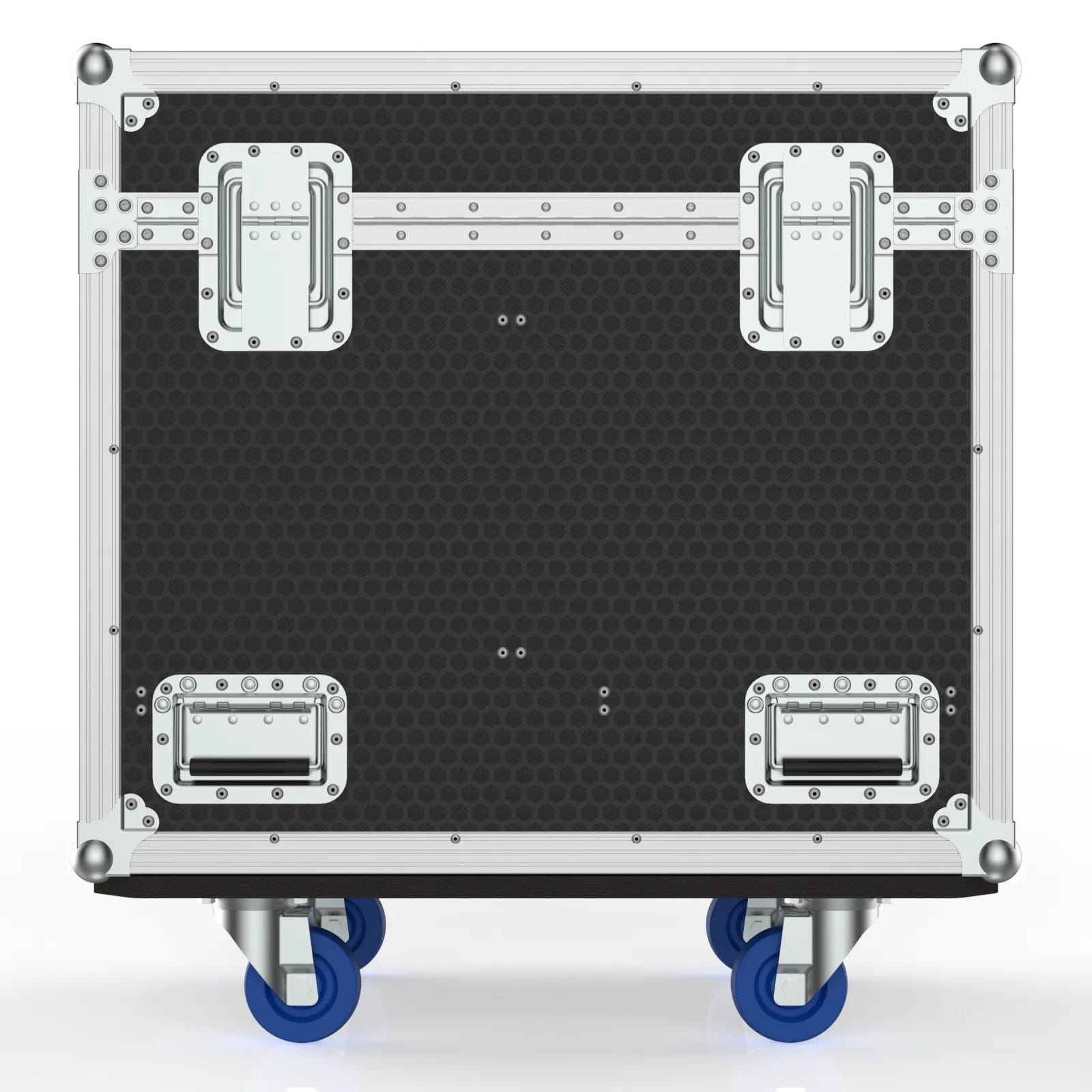

ROAD CASE FOR DOUBLE GLP JDC2‑IP LED HYBRID STROBE FIXTURE

$1,014.36

This road case is purpose‑built for safely transporting two GLP JDC2‑IP LED Hybrid Strobe Fixtures, the kind of medium‑sized but surprisingly heavy units that touring crews know all too well. The case uses a top‑hinged lid for easy loading, with thick foam lining wrapped around each fixture to keep them snug on the road. Inside, you’ll also find dedicated storage for JDC2‑IP light filters, including two foam‑lined compartments and two additional pockets. With solid wheels, reinforced hardware, and truck‑friendly dimensions, the case is ready for the demands of concert touring and live events. Whether you’re moving GLP units or similar fixtures from other brands, this case keeps everything organized, protected, and easy to handle.

SKU:

CP8685-GLP-JDC2IP

Categories: Lighting & FX Production, Moving Head Light Cases Tags: GLP, road case, strobe fixture, top hinged lid

Description

Product Specifications

Package Weight and Package Dimensions are for shipping purposes only. Actual product weight and dimensions can be found in the 2D drawing PDF.

| Weight | 58 kg |

|---|---|

| Dimensions | 61 × 81 × 85 cm |

| Hardware Brand |

Penn Elcom and Armorcases mixed |

| Panel |

12MM Birch Veneer Plywood Panel |

Technical Doc.

| 2D Drawing | Download |

Designed for the GLP JDC2‑IP and Similar Heavy LED Strobe Fixtures

This transport case is built specifically for the GLP JDC2‑IP, a medium‑sized but undeniably heavy LED Hybrid Strobe Fixture with a tilting head. Anyone who has handled one knows it’s not the kind of light you casually toss into a van. This case gives it the respect—and protection—it deserves. It holds two units comfortably, with enough internal structure to keep them separated, cushioned, and secure during long touring schedules.

Although tailored for the JDC2‑IP, many fixtures with similar shapes and head‑tilt mechanisms from other brands can also fit with minor adjustments. Touring crews often mix gear, and this case is designed with that reality in mind. If the fixture is in the same family of “medium but heavy LED hybrid strobes,” chances are this case can be adapted to suit it.

Built with Durable Materials and a Consistent, High‑Precision Manufacturing Process

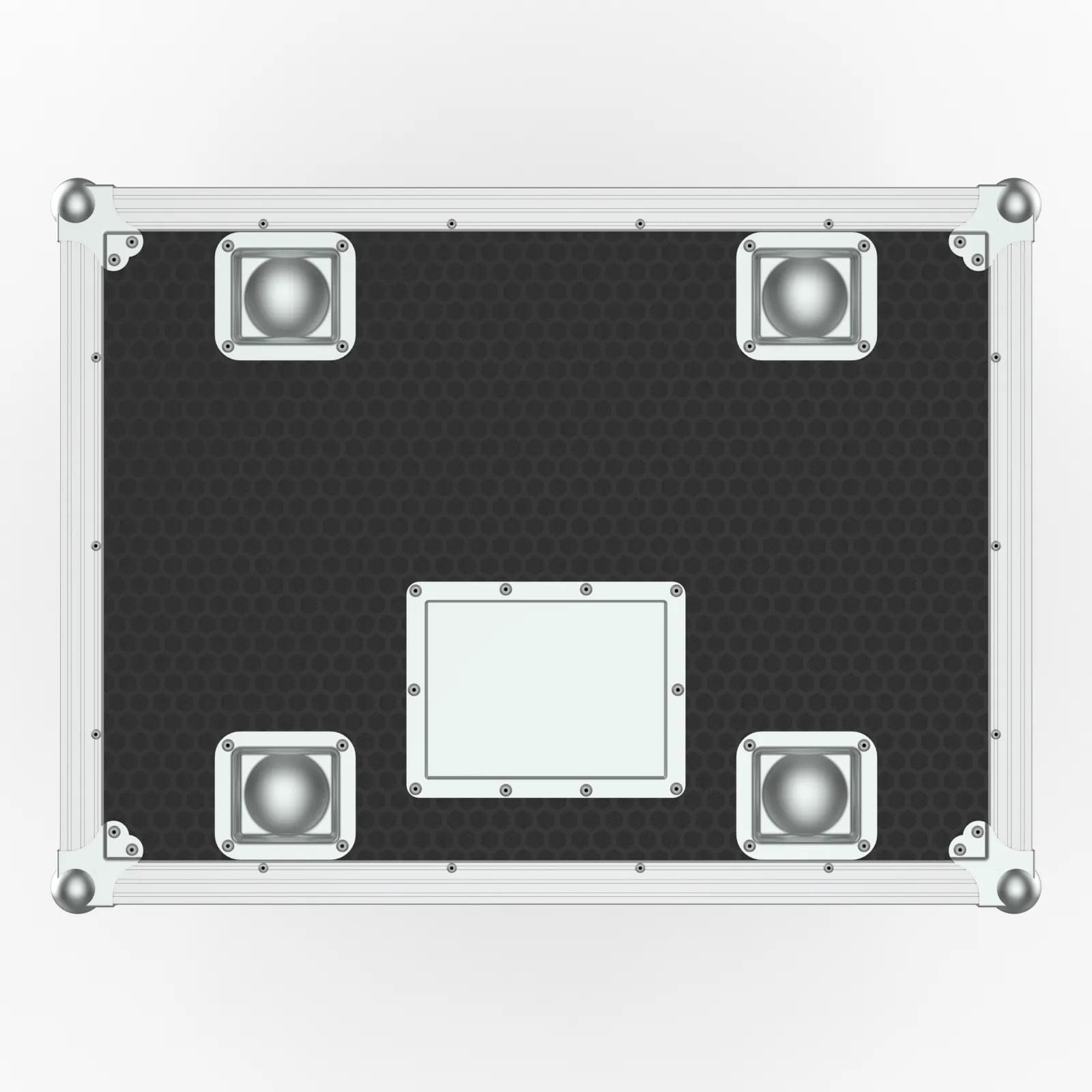

The exterior is constructed from 12mm WBP birch veneer laminated plywood, a material chosen for its ability to handle the unpredictable mix of heat, moisture, and general chaos that comes with touring. The panels are paired with 2mm heavy‑duty corner and edge extrusions, along with a combination of Penn Elcom and Armor hardware. The result is a case that feels solid in the hands and even more solid when stacked in a truck pack.

Every panel and foam insert is precision‑cut using CNC machinery, ensuring accuracy down to the millimeter. This means the fixtures sit exactly where they should, without wobble or pressure points. Once the components are cut, our trained and experienced assembly team takes over. They’ve built enough cases to know when something feels right—and when something needs a second look. After assembly, each case goes through a standard QC process that checks alignment, hardware installation, foam fit, and overall finish.

We use this same manufacturing approach across our product line, but each case still gets its own personality. Different fixtures require different internal layouts, and our team adjusts the design accordingly. So while the process is consistent, the results are always tailored.

Functional Features That Make Touring Life Easier

The most noticeable feature is the top‑hinged lid. Instead of wrestling with side‑loading compartments or awkward angles, you simply open the lid and lower the fixtures straight in. For a heavy strobe fixture with a tilting head, this is a small but meaningful quality‑of‑life upgrade.

Inside, thick layers of foam wrap around the fixtures and the lid. This isn’t just for cushioning—it also keeps the fixtures from shifting when the truck hits that one pothole everyone pretends not to notice. The foam is dense enough to absorb impact but soft enough to avoid scratching or stressing the fixture’s housing.

The case includes two dedicated storage spaces for JDC2‑IP light filters, each with bottom foam lining for extra protection. On top of that, two additional pockets provide room for more filters or small accessories. Everything stays organized, and nothing gets lost under cables or clamps.

Mobility is handled by solid wheels and well‑placed handles, making it surprisingly easy to move despite the weight of the fixtures inside. The dimensions are truck‑friendly, so it stacks neatly with other cases. A label dish is included for quick identification—because no one wants to open six cases just to find the one with the strobes.

Altogether, this case is built to make life easier for touring crews, rental houses, and production teams who rely on the GLP JDC2‑IP or similar fixtures. It protects the gear, speeds up load‑ins, and keeps everything organized, all while holding up to the realities of the road.

What type of transport cases do you guys sell?

We design and manufacture reusable transport protective cases for different applications and industries including touring, events, medical, trade shows, defence, etc. We have been accumulating our standard case designs and most of these are listed on our website with prices available for order.

Currently, we do not stock ready-made cases at Sydney so our standard designs will also come with a lead time. However, we plan to stock some selected products from 2026.

We design and manufacture reusable transport protective cases for different applications and industries including touring, events, medical, trade shows, defence, etc. We have been accumulating our standard case designs and most of these are listed on our website with prices available for order.

Currently, we do not stock ready-made cases at Sydney so our standard designs will also come with a lead time. However, we plan to stock some selected products from 2026.

Where are your cases built?

ARMOR currently owns and operates a manufacturing facility located in Auburn, NSW in Australia. Apart from that we have OEM factories in Guangzhou, China for our bulk orders for Australia and international customers. Our Auburn workshop mainly focus on small and urgent domestic orders with less than 5 weeks lead time, while the Guangzhou OEM factories work on non-urgent orders with a lead time of 8-10 weeks, with MOQ of 10 per product and can ship internationally.

Are there any differences in build quality between the 2 locations?

Road cases built in both workshops are exactly the same. They are based on the same product designs and specifications including materials and manufacturing processes. Both locations are equipped with high precision machineries including CNC routers operated by experienced staff.

How long will delivery take?

Our Sydney workshop can respond to urgent orders and lead time can be 1 to 5 weeks depending on case design process and current workload at the workshop.

Manufacturing lead time from China location is usually 4 weeks. On top of that there will be shipping lead time depending on customer locations. For example, shipping from China to Australia by sea, typically takes another 4 weeks.

What information should I provide when asking for a quote?

- A link to or photo of a similar case and what changes need to be made (if there are any). Our Instagram feed can be a great source of information on previous built cases.

- If engraving is required.

- Internal dimensions of case, or outer dimensions of the items that would be stored in them.

- For complex items, a CAD model or drawing would come in handy. If not, please let us know to arrange a 3D scan of the item.

- Your billing and shipping addresses. Please confirm if it’s a business address or not, and if you have a forklift onsite.

Your Case is Our Case

This light fixture case features:

We put a lot of efforts in our case designs as well as built quality and workmanship. We design our cases to be long lasting, easy to use and appreciated by our customers.

- Low base, edge customer board, smaller castor wheels for best stability

0%

Why Choose Our Cases

Durability

Our custom built flight and road cases are backed with 5 years warranty. Our transport cases are built by experienced case builders using premium hardware and panels.

Customization

Our case designers are experienced with case designs. 3D scanning technologies and CAD software enable them to accurately design and visualize the cases before production.

Precision Manufacturing

We invest in the best technologies in case making industry including CNC routers, foam cutters, laser cutters, pneumatic aluminum cutting machines, hole punching machines, etc. These tools help to ensure manufacturing accuracy and consistency.

Value to Customer

Production automation using new technology and reduce labor cost by embracing an "Local workshop plus Overseas Factory" model allows us to provide better value for our customer. Covering both urgent and non-urgent orders while not compromising on quality.

Small Wheels, Closer to Edges

Our premium light fixture road case combines style and durability with its glossy black honeycomb finish and EVA foam padding. Designed to hold up to 2 LED strobe fixtures, it features a hinged top lid.

SEND US A MESSAGE

Order Process Information

Payment Information

Do you require a deposit for custom cases?

Yes. Unless you are one of our credit customers, we do require a minimum 50% payment upfront to confirm the sales order and commence work. We do not provide a product design for review until there is a sales order.

Will you provide a CAD drawing for review?

Yes. We always provide 2D pdf drawings with key measurements and notes for comments and confirmation, before production commences. This is usually provided approx. 1 week after a sales order is confirmed.

What is your warranty policy?

Based on our market research we are currently, as of 2025, offering the best product guarantee among cases manufacturers and resellers in Australia. Our road cases come with 5 years warranty, excluding damages due to lack of care. For detailed warranty policy please continue reading.

Can I change or cancel my order?

Our sales quote is based on product specifications provided by our customers. If new information or requests is made after a sales order is confirmed, we will need to review the original sales quote to see if surcharges are justified. The review will take into consideration of any work done which is wasted due to the new request.

Additional information

| Weight | 58 kg |

|---|---|

| Dimensions | 61 × 81 × 85 cm |

| Hardware Brand |

Penn Elcom and Armorcases mixed |

| Panel |

12MM Birch Veneer Plywood Panel |

Reviews (0)

Rated 0 out of 5

0 reviews

Rated 5 out of 5

0

Rated 4 out of 5

0

Rated 3 out of 5

0

Rated 2 out of 5

0

Rated 1 out of 5

0

Be the first to review “ROAD CASE FOR DOUBLE GLP JDC2‑IP LED HYBRID STROBE FIXTURE” Cancel reply

Related products

ADAMS PROFESSIONAL GEN 2 29INCH TIMPANI RAMP ROAD CASE

$2,250.00This ramp road case is purpose‑built for the Adams Professional Gen 2 29inch, a large and heavy wheeled musical instrument that deserves a little extra pampering on the road. Designed for easy front loading, the case features a hinged lid with an integrated ramp that lets you roll the instrument straight in without the usual wrestling match. Its truck‑friendly dimensions and solid wheels with brakes make moving it around surprisingly manageable, even when the gear inside weighs more than your drummer’s entire kit. Built with durability in mind and fitted with premium hardware, this case gives your instrument the protection it needs while keeping transport simple and stress‑free.

LAFIMA PA-SPB-0024-000 24INCH BAROQUE TIMPANI ROAD CASE

$1,821.75This road case is purpose‑built for the Lafima PA-SPB-0024-000, a 24inch beautifully crafted baroque timpani that deserves more than a casual ride in the back of a truck. Designed with a top‑entry hinged lid, it makes loading and unloading surprisingly easy for an instrument of this size. Inside, a generous layer of professionally arranged foam keeps the timpani snug and protected from bumps, shakes, and the occasional over‑enthusiastic stagehand. The case rolls smoothly on durable wheels and features truck‑friendly dimensions, making transport far less dramatic than the performances the timpani is meant for. Whether used for touring, storage, or venue‑to‑venue travel, this case keeps your instrument safe and ready for the next show.

MULTI‑DRAWER LARGE ROAD CASE WITH 6 DRAWERS & 14 SHELVES

$4,657.54This multi‑drawer large road case is built for anyone who needs serious storage without the drama. Designed with a single hinged front lid, recessed handles, and four braked castor wheels, it keeps your gear secure and easy to move. Inside, you’ll find a mix of drawer sizes and shelves, all wrapped in EVA foam to protect heavier items — even the kind that like to bite back, like metal hand cymbals. Whether you’re touring, organizing a studio, or just tired of gear chaos, this case offers a clean, structured way to keep everything in its place. It’s practical, durable, and surprisingly easy to handle for something this big.

RAMP ROAD CASE FOR ADAMS LARGE WHEELED CONCERT BASS DRUM

$4,614.23This transport case is purpose‑built for the Adams Concert Bass Drum, a seriously large instrument that deserves equally serious protection. Designed with a front hinged lid and integrated ramp, it lets you roll the drum and its wheeled stand straight in without any heavy lifting. The case’s truck‑friendly dimensions, reinforced build, and smooth‑rolling wheels make moving a 60‑inch drum feel far less dramatic than it sounds. Whether you’re touring, storing, or simply trying to keep your prized percussion gear safe from bumps and bruises, this case offers a practical and reliable solution. It fits one drum and can be adapted for similar oversized models from other brands.

Reviews

Clear filtersThere are no reviews yet.