Choosing a Flight Case Manufacturing Partner in China: A Due-Diligence Framework for Bulk Buyers

China has become a critical manufacturing base for flight cases used by production companies, equipment manufacturers, and distributors worldwide. For buyers placing container-level or repeat orders, however, sourcing decisions involve far more than comparing prices or approving a single prototype.

At scale, the real challenge is consistency. The question bulk buyers must answer is not whether a factory can build a good-looking road case, but whether it can reproduce the same product accurately, reliably, and predictably across hundreds of units and multiple production runs.

This article outlines a practical due-diligence framework for evaluating a flight case manufacturer in China, written specifically for bulk buyers who need long-term reliability rather than short-term savings.

Why Bulk Buyers Need a Different Evaluation Approach

Many sourcing issues arise when large orders are evaluated using small-order logic. A visually acceptable sample can hide problems that only surface during volume production. Differences in internal structure, foam fit, material quality, or assembly methods often appear gradually, becoming costly only after products are already in circulation.

For distributors and production companies, these issues can lead to increased damage claims, warranty exposure, and operational disruption. As order quantities grow, so does the importance of engineering control, manufacturing discipline, and documentation.

A serious evaluation of a road case manufacturer in China therefore needs to look beyond unit price and capacity, and focus on how design intent is defined, controlled, and protected throughout production.

Design Control and Engineering Ownership

One of the most important but least visible factors in flight case manufacturing is design ownership. Many factories are capable of manufacturing from drawings, yet fewer maintain a structured system to control design intent over time.

In large-scale production, unclear design control can result in gradual changes to internal layouts, foam tolerances, or structural elements. These changes are not always malicious; they often occur when designs are interpreted differently by different teams or adjusted informally during production.

Manufacturers that use professional 3D CAD platforms such as SolidWorks are better positioned to manage this risk. Centralised digital models allow precise equipment geometry to be captured, complex internal structures to be defined accurately, and revisions to be documented and controlled. When designs are managed as engineering assets rather than reference sketches, they can scale without losing integrity.

For bulk buyers, this level of design control is essential to maintaining consistency across production runs and future reorders.

Manufacturing Precision and Repeatability

The ability to produce one high-quality case does not necessarily indicate the ability to manufacture hundreds of identical units. Repeatability is where many suppliers struggle.

Factories equipped with CNC routers, precision cutting systems, and controlled assembly processes are better able to maintain dimensional accuracy over time. These tools reduce reliance on manual interpretation and help ensure that parts produced today match those produced weeks or months later.

In contrast, manufacturing environments that rely heavily on manual cutting and flexible assembly methods can experience greater variability as volume increases. While such approaches may reduce initial cost, they often introduce inconsistency that becomes visible only after cases are deployed in the field.

For buyers placing container orders, manufacturing discipline is not a technical preference; it is a commercial necessity.

Material Quality and Long-Term Performance

Material specifications are frequently listed but not always explained. For bulk buyers, understanding how materials behave under real-world conditions is more important than reading a generic component list.

Premium road cases typically use WBP-grade laminated birch plywood due to its resistance to moisture and its structural stability over time. Lower-grade alternatives may perform adequately in controlled environments but can delaminate or warp when exposed to humidity, heat, or repeated handling.

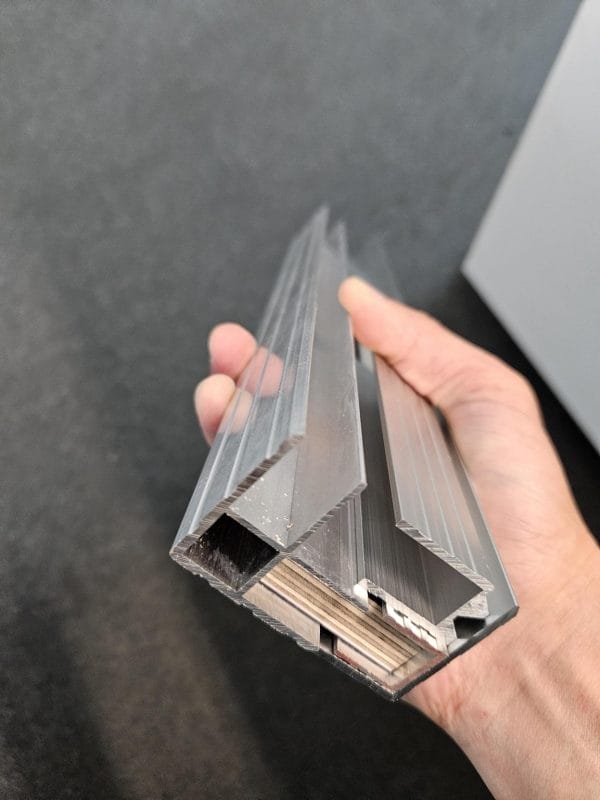

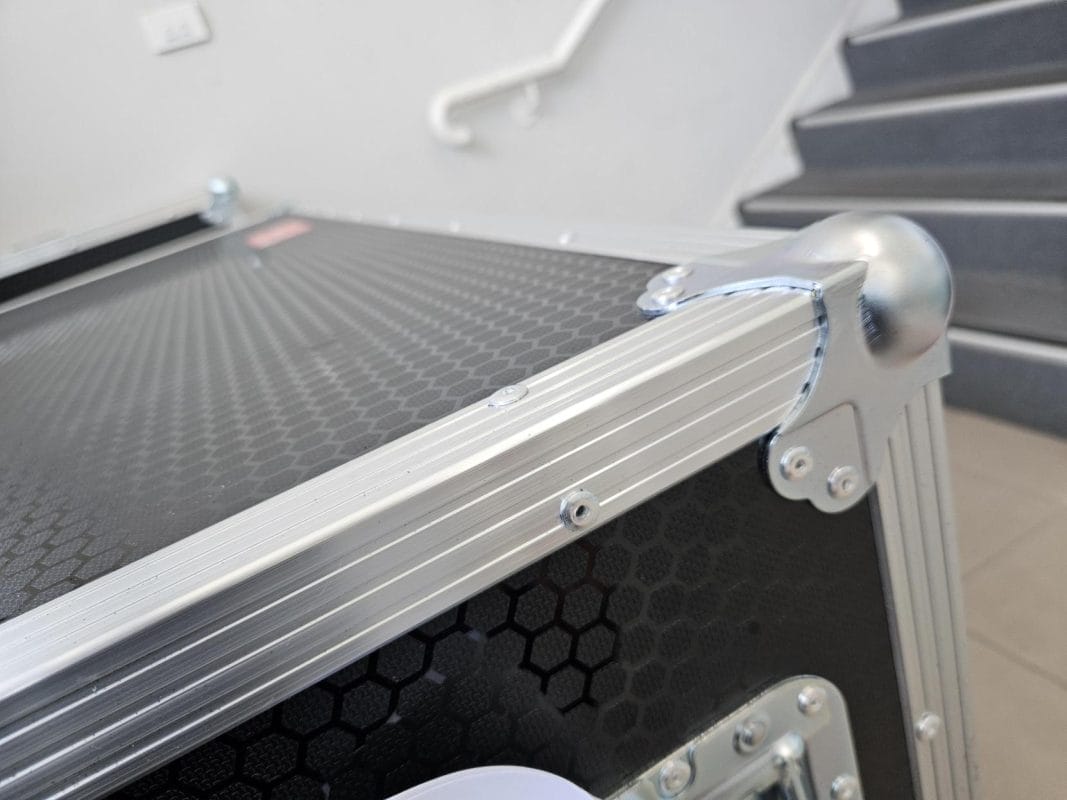

Edge protection is another critical area. Aluminium extrusions and steel ball corners are subject to repeated impact during touring and freight. Thicker components, such as 2 mm extrusions and 2 mm steel corners, offer greater resistance to deformation and help preserve case integrity throughout its service life.

Hardware selection also plays a role in long-term reliability. Recognised brands such as Penn Elcom, or equivalent professional hardware, are designed for repeated use and predictable load performance. Adhesives, though often overlooked, are equally important. Heat-resistant industrial adhesives help prevent internal separation during transport and storage in warm conditions.

Individually, these choices may appear minor. Collectively, they determine whether a case remains functional after years of use or begins to fail prematurely.

Long-Term Partnership Versus Transactional Supply

Bulk buyers rarely benefit from changing suppliers frequently. Stability in design, documentation, and production processes supports predictable reorders and reduces operational friction.

A manufacturing partner capable of supporting long-term SKU stability, controlled revisions, and consistent lead times offers value that extends well beyond unit pricing. This distinction becomes increasingly important as organisations scale their operations and product ranges.

Applying This Framework in Practice

Manufacturers that combine centralised product development, engineering-led design using SolidWorks, precision CNC manufacturing, and disciplined material specification are structurally better suited to serve bulk buyers.

This approach underpins the operating model of Armor Cases Sydney, where product development is informed by real-world use, and Armor Cases Guangzhou, where those designs are executed at scale with controlled processes. The result is alignment between design intent, manufacturing execution, and long-term consistency.

Final Considerations for Procurement Teams

Choosing a flight case manufacturer in China is a long-term sourcing decision. For bulk buyers, the most significant costs are rarely found in unit pricing, but in inconsistency, rework, damage claims, and lost time.

Applying a due-diligence approach that prioritises design control, manufacturing precision, and material integrity provides a more reliable foundation for scalable production. Buyers looking to apply these principles in practice may find it useful to review Armor’s custom flight and road case manufacturing capabilities for bulk and container-level orders.